Understanding The Role of Material Selection in Forging

Forging is an intricate craft that requires many elements; the role of material selection plays a key role in the forging process, ensuring durability and success are achieved in the final product.

At B.B. Price, we understand the significance of different materials in forging and are here to offer unrivalled advise for every project that we complete. Here, we unpack the importance of material selection in forging in order to achieve excellence in all forged products.

Material Selection in Forging

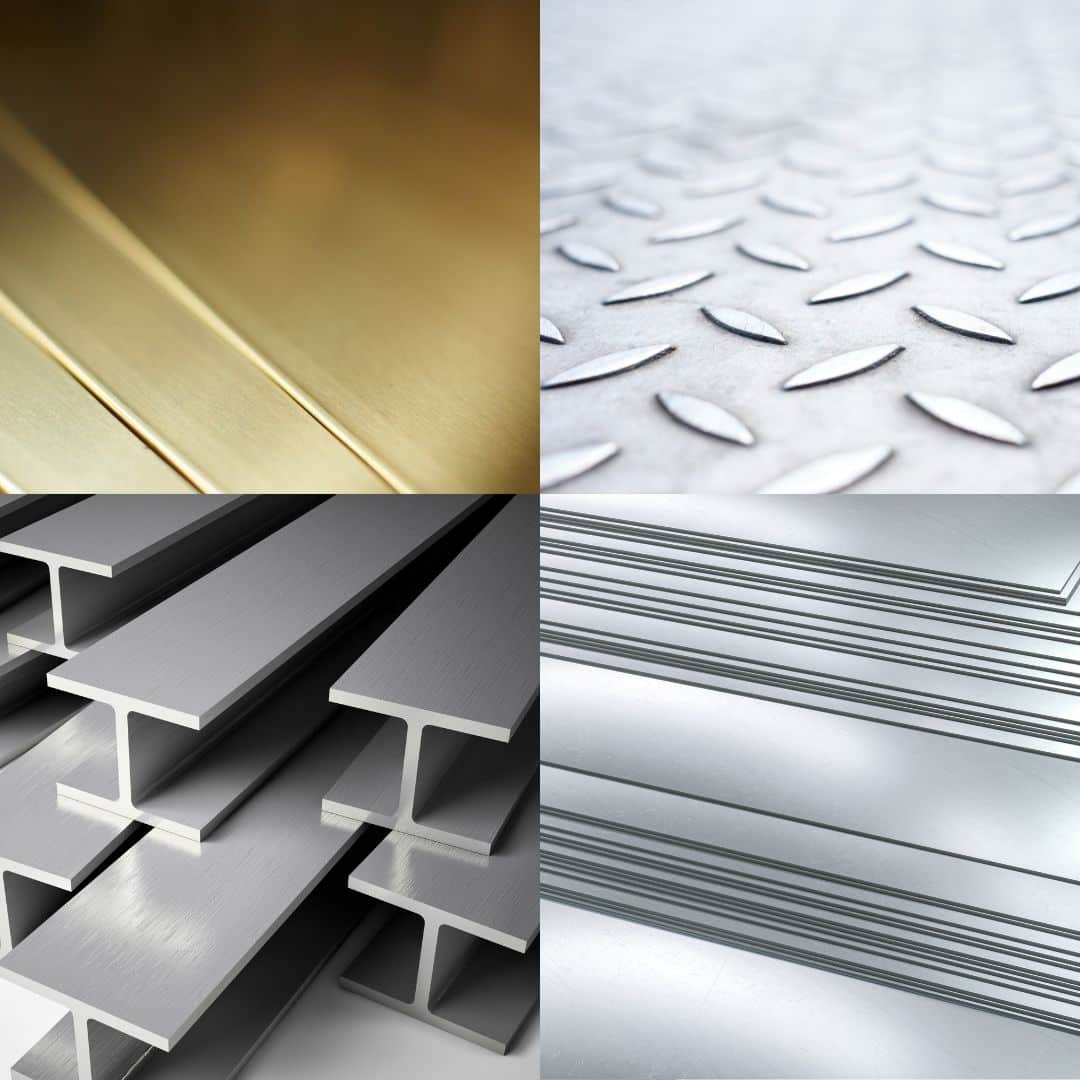

The world of forging offers a diverse range of materials to choose from, including steel, aluminium, and exotic alloys.

Why Material Selection Matters

The right material selection in forging is a strategic decision that can impact the overall performance, durability, and cost-effectiveness of a project; it is not merely a preference. But why does material selection in forging really matter?

- Strength & Durability: Different materials have varied levels of strength and durability making it crucial that the right material selection takes place. This will result in your product being able to withstand application stresses and loads.

- Corrosion Resistance: For components that will be exposed to harsh environments or corrosive substances, selecting a material with high corrosion resistance is essential. This ensures longevity and reliability.

- Temperature Resistance: When components will be exposed to high temperatures or thermal cycling, it is important to select a material that has excellent temperature resistance. This will prevent premature failure.

- Machinability: Some materials are easier to machine and forge than others. Selecting a material that can be easily machined may result in streamlining the manufacturing process and reduce the overall production costs.

Types of Materials Used in Forging

There are a number of types of materials used in forging. At B.B. Price, some of the common materials selected for forging are:

- Steel: This material is renowned for its strength, durability, and versatility. It is the most commonly used material for forging projects because of these features and the wide range of steel grades available. This allows for a more tailored solution to meet specific project needs.

- Aluminium: This material is known to be lightweight yet incredibly strong. It is often favoured for its resistance capabilities and its thermal conductivity. This is typically selected for aerospace, automotive or construction projects.

- Brass and Cooper: With excellent electrical conductivity and corrosion resistance, these materials are often utilised in electrical or plumbing works. It is also commonly forged for decorative or artistic means.

- Titanium: This material offers high strength to weight ratio, corrosion resistance and biocompatibility. For these reasons it is often used in aerospace, medical and automotive components where lightweight yet durable components are required.

If you are looking at your forging project and are unsure on the type of material that you need to select for best results, contact B.B. Price today. Our team of experts can help ensure that your project is completed with the right material selection.

The Difference at B.B. Price

At B.B. Price, our forging experts are material experts. With extensive experience in forging, we understand the nuances of each material and how to leverage its properties to forge components of unparalleled excellence and quality.

Whether you are seeking highly durable steel components for industrial applications, or a lightweight aluminium part for aerospace projects, we have the expertise and capabilities to bring your visions to life. With forging facilities that boast a drop forging capacity of up to 1000 tonnes using screw press and steel selections with diameters of 10mm to 50mm we are able to complete your projects within your deadlines without compromising on quality and standards.

Material selection in forging is more than just a choice, it is a strategic decision determined by your project requirements and desires for success. With B.B. Price, you can be sure that every component forged utilises the finest materials with precision and excellence. Contact our team today to discuss your project and experience our commitment to quality and excellence.