Are you searching for excellence in "Closed Die Forging Halesowen"? Look no further than B.B. Price, your local experts in the art and science of forging. In the heart of Halesowen, we redefine the possibilities of closed die forging, providing unparalleled precision, strength, and innovation for your projects.

As local experts based in the heart of The Black Country, we take pride in manufacturing the best quality products for every client’s project, ensuring every piece is durable and made with precision for application.

If you need closed die forging Halesowen, contact B.B. Price today.

What is Closed Die Forging?

Closed Die Forging, also known as impression die forging, is a precision forging process where metal is shaped by placing it within the confines of a set of dies. These dies contain a cavity that forms the desired shape when the metal is compressed.

At B.B. Price, Closed Die Forging is not just a process; it's a craft that combines traditional artistry with cutting-edge technology. All of our skilled forgers have been fully training the art of closed die forging to ensure that every piece is forged to perfection.

If you want to know more about our forging techniques, take a look online today.

Applications of Closed Die Forging

Closed Die Forging finds its applications across a wide spectrum of industries, offering solutions for components that demand precision, strength, and reliability. Some notable applications include:

- Automotive Components: Closed Die Forging is extensively used in the automotive industry for manufacturing critical components like connecting rods, crankshafts, and gears. The precision and strength obtained through this process contribute to the overall performance and safety of vehicles.

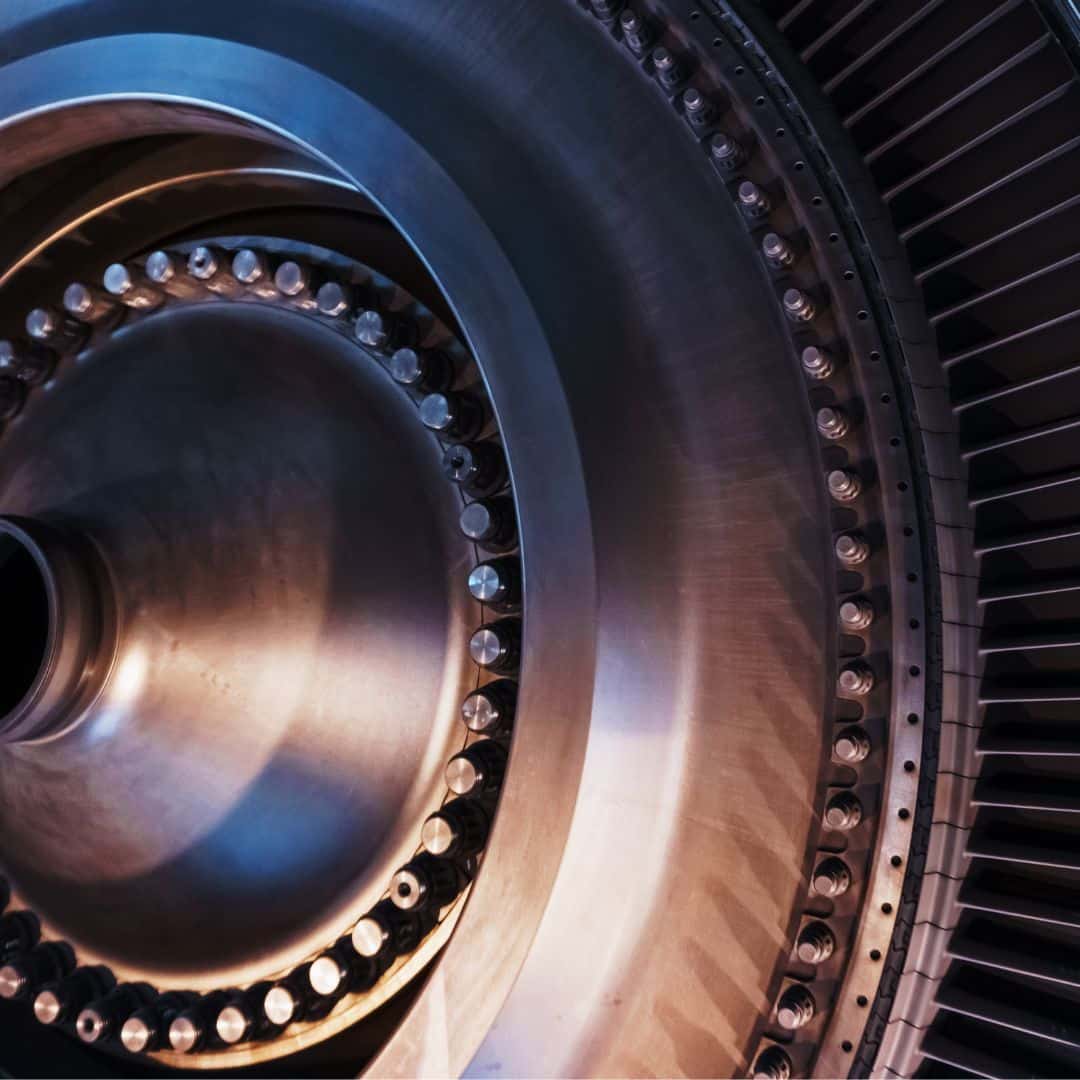

- Aerospace Parts: In the aerospace sector, where precision and durability are non-negotiable, Closed Die Forging is employed to create components such as turbine discs, landing gear parts, and structural elements. The method ensures compliance with stringent industry standards.

- Oil and Gas Equipment: The demanding conditions of the oil and gas industry require components that can withstand extreme environments. Closed Die Forging is utilised for manufacturing valves, flanges, and other critical parts that require both strength and corrosion resistance.

- Industrial Machinery: Closed Die Forging plays a crucial role in the production of heavy-duty industrial machinery components like gears, shafts, and fasteners. The method ensures that these components can withstand the rigors of continuous operation.

- Defence and Military Equipment: In the defence sector, where reliability and precision are paramount, Closed Die Forging is employed for producing components such as artillery shells, firearm parts, and other critical equipment.

Benefits of Closed Die Forging for Your Project

As with every method of forging, closed die forging Halesowen has its own unique set of benefits, including:

- Precision Engineering: Closed Die Forging ensures the creation of components with intricate details and precise tolerances. This method excels in achieving complex shapes with consistency and accuracy.

- Superior Strength: The controlled compression in Closed Die Forging results in a refined grain structure, imparting superior strength and durability to the forged components. This is especially crucial in applications where structural integrity is paramount.

- Cost-Effective Solutions: While delivering top-notch quality, Closed Die Forging remains a cost-effective choice. The efficiency of the process, coupled with the durability of the end product, makes it a wise investment for various projects.

Other Forging Techniques at B.B. Price

At B.B. Price, we understand that every project is unique, and forging techniques need to be tailored to specific requirements. In addition to Closed Die Forging Halesowen, we offer a diverse range of forging processes:

- Open Die Forging: Ideal for creating large, complex shapes, Open Die Forging involves shaping metal between dies that do not completely enclose the material. This method offers versatility and flexibility in design.

- Upset Forging: Also known as "heading," this technique involves compressing the end of a pre-heated metal bar, enhancing its strength, density, and thickness. It's a powerful method for creating robust components.

- Hand Forging: Elevating craftsmanship to an art form, Hand Forging at B.B. Price involves the meticulous shaping of metal by skilled artisans. This hands-on approach delivers truly unique and custom components.

Find the right method of forging for your needs or get in touch with our team today for help and guidance.

Why Choose B.B. Price as Your Local Experts

B.B. Price have been in the forging industry for over 130 Years, establishing a business that fulfil the needs of Halesowen and to surrounding areas. With a wealth of knowledge and expertise, there are a number of reasons why B.B. Price are your local experts for closed die forging.

- Heritage of Excellence: With roots deeply embedded in Halesowen, B.B. Price brings a heritage of forging excellence to your doorstep. Our commitment to the local community is reflected in every project we undertake.

- State-of-the-Art Facilities: Our modern facilities equipped with advanced technology ensure that every forging project, including Closed Die Forging, meets the highest standards of precision and quality.

- Consultative Approach: We understand that communication is key. Our consultative approach involves close collaboration with clients, ensuring that your project specifications are not just met but exceeded.

Elevate Your Projects with B.B. Price

Whether you're navigating the intricacies of Closed Die Forging Halesowen or seeking a reliable partner for your forging needs, B.B. Price is your trusted source. Contact us today to discuss your project and let the precision of Closed Die Forging redefine the strength and innovation of your components.

Experience the excellence of forging with B.B. Price – where local expertise meets global standards.